Quality

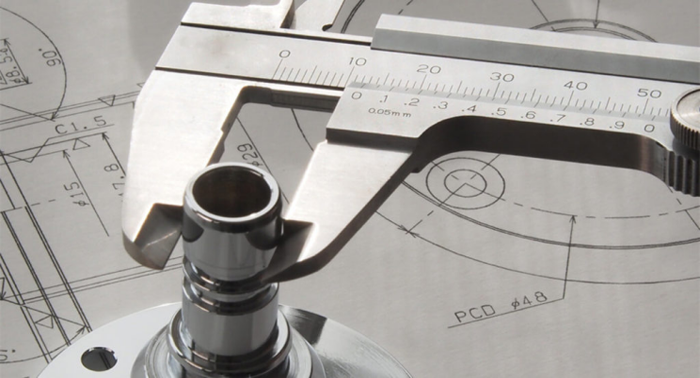

Material Identification, Quality Inspection, and Testing

We take care every details on mold design and manufacture, control each step.

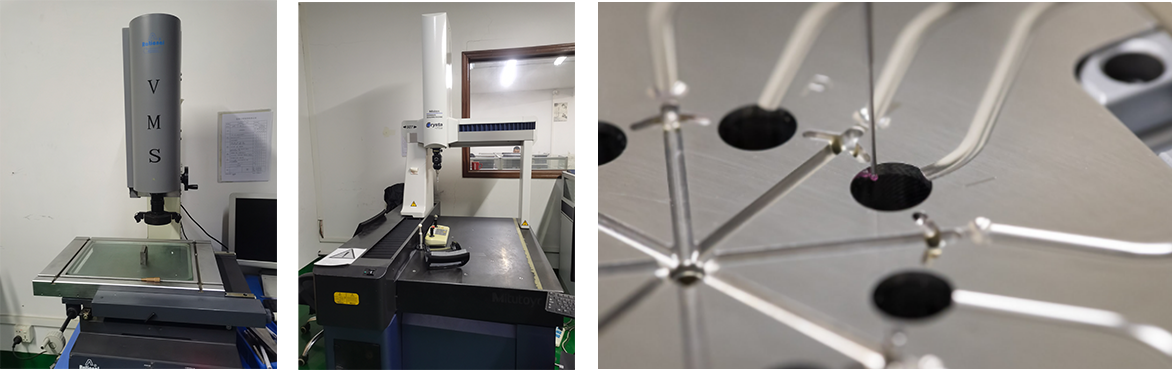

Ensuring consistency of high-quality requires a very strict processing control techniques combined with state-of-the-art equipment. In TIPTOP we take advanced steps in part inspection measurement and all testing equipment are in-house in order to check and quality incoming raw material from material vendor to advancing in in-house production advancement. Our modern material and part inspection equipment laboratory ensures that all the parts, components and material meet our customer’s standard specifications.

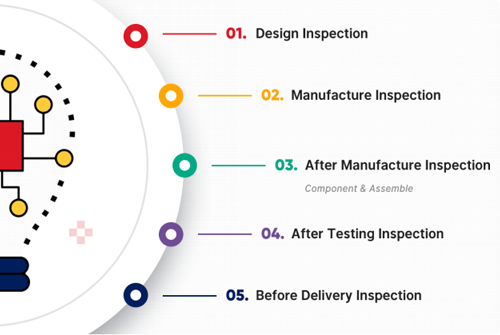

We follow these steps for every project we handle for quality assurance:

Main Quality Control

· Mould design control

· Mould Steel Hardness Inspection

· Mould steel dimension control

· Mould Core and Cavity Steel Dimension Inspection

· Machining in-process inspection

· Heat treating with certification

· Electrode / sample / mould inspection

· Mould pre-assembly inspection

· Tool trial data record

· Final inspection before shipment

· Mould maintenance

· Complete and traceable documentation

· Mould design control

· Mould Steel Hardness Inspection

· Mould steel dimension control

· Mould Core and Cavity Steel Dimension Inspection

· Machining in-process inspection

· Heat treating with certification

· Electrode / sample / mould inspection

· Mould pre-assembly inspection

· Tool trial data record

· Final inspection before shipment

· Mould maintenance

· Complete and traceable documentation

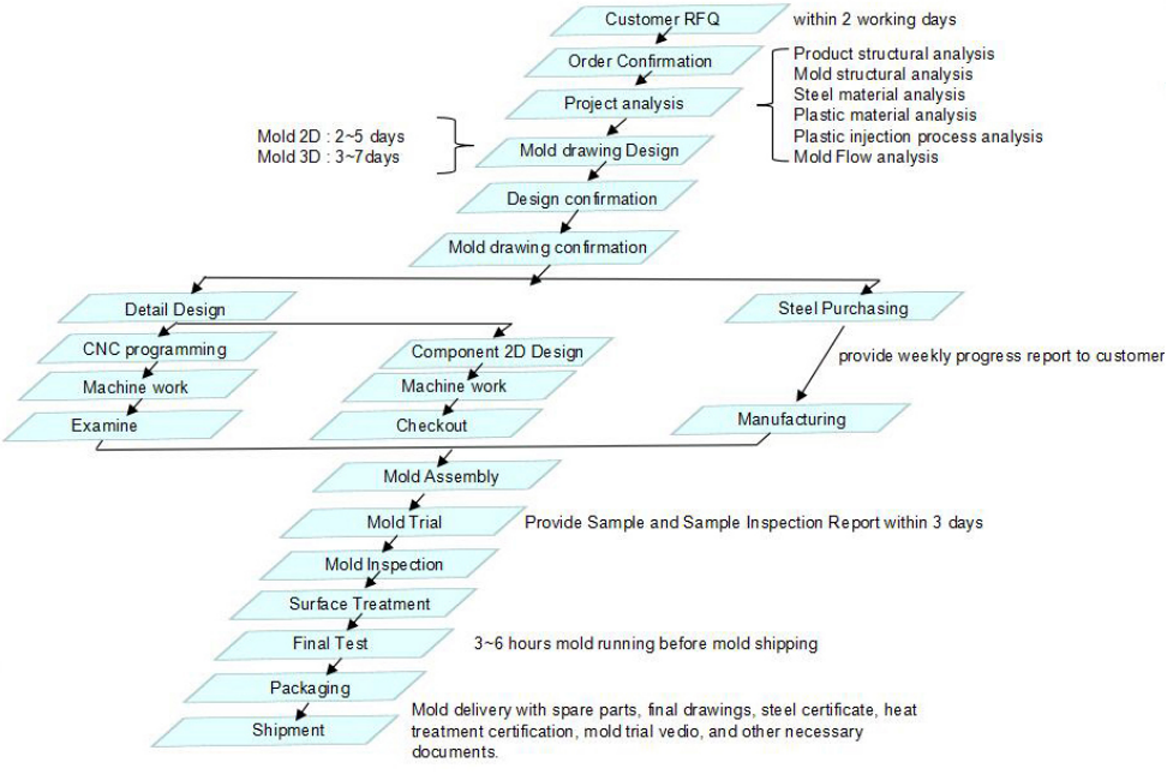

Our Work Flow Chart